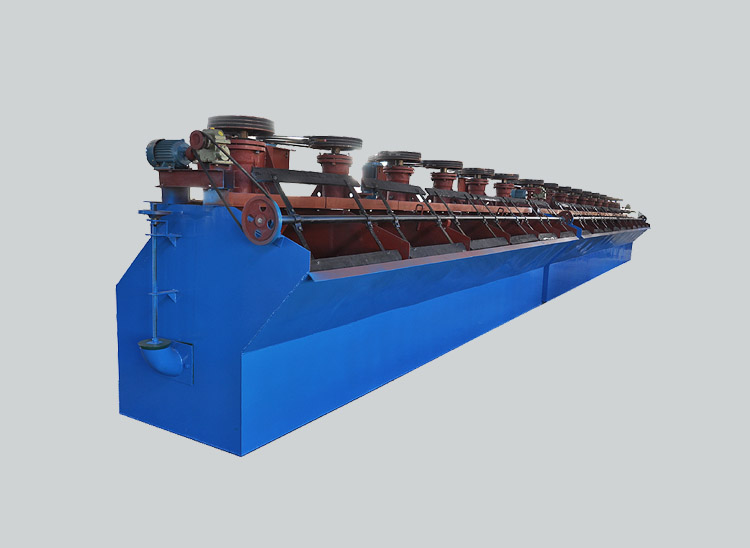

6S shaking table

Shaking Tables are designed to wet gravity-based separation of minerals and other granular materials. It is effective in processing precious and base metal, rare metal and non-metallic minerals.

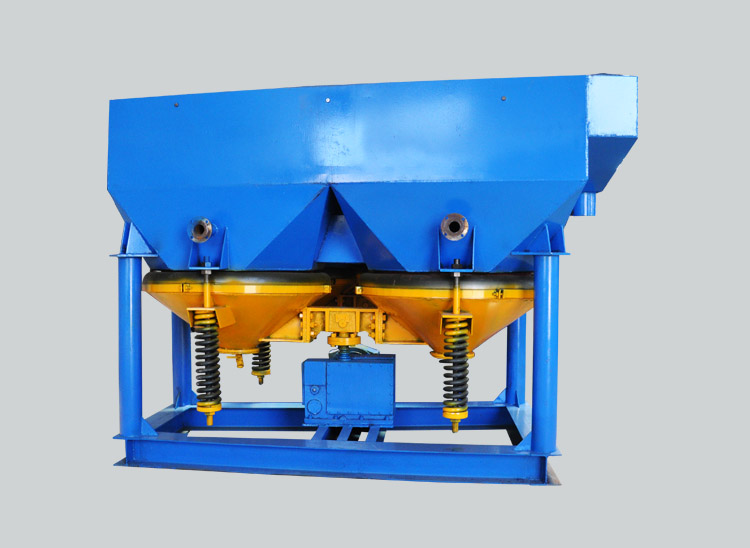

Category: Gravity separation equipment

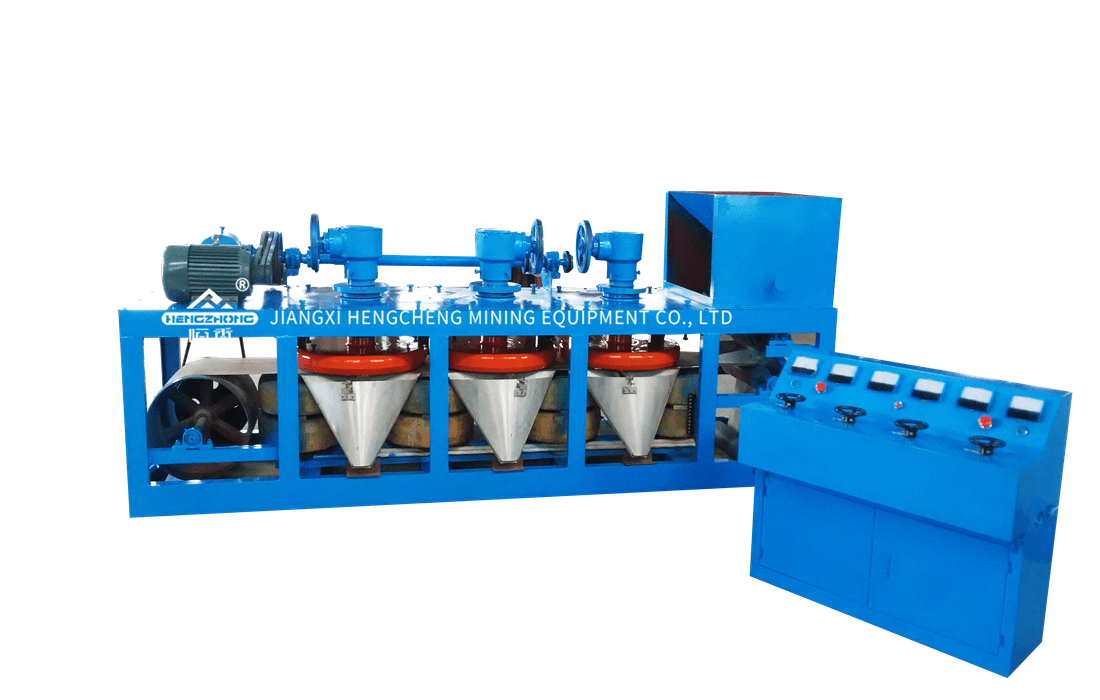

Machine Details Show

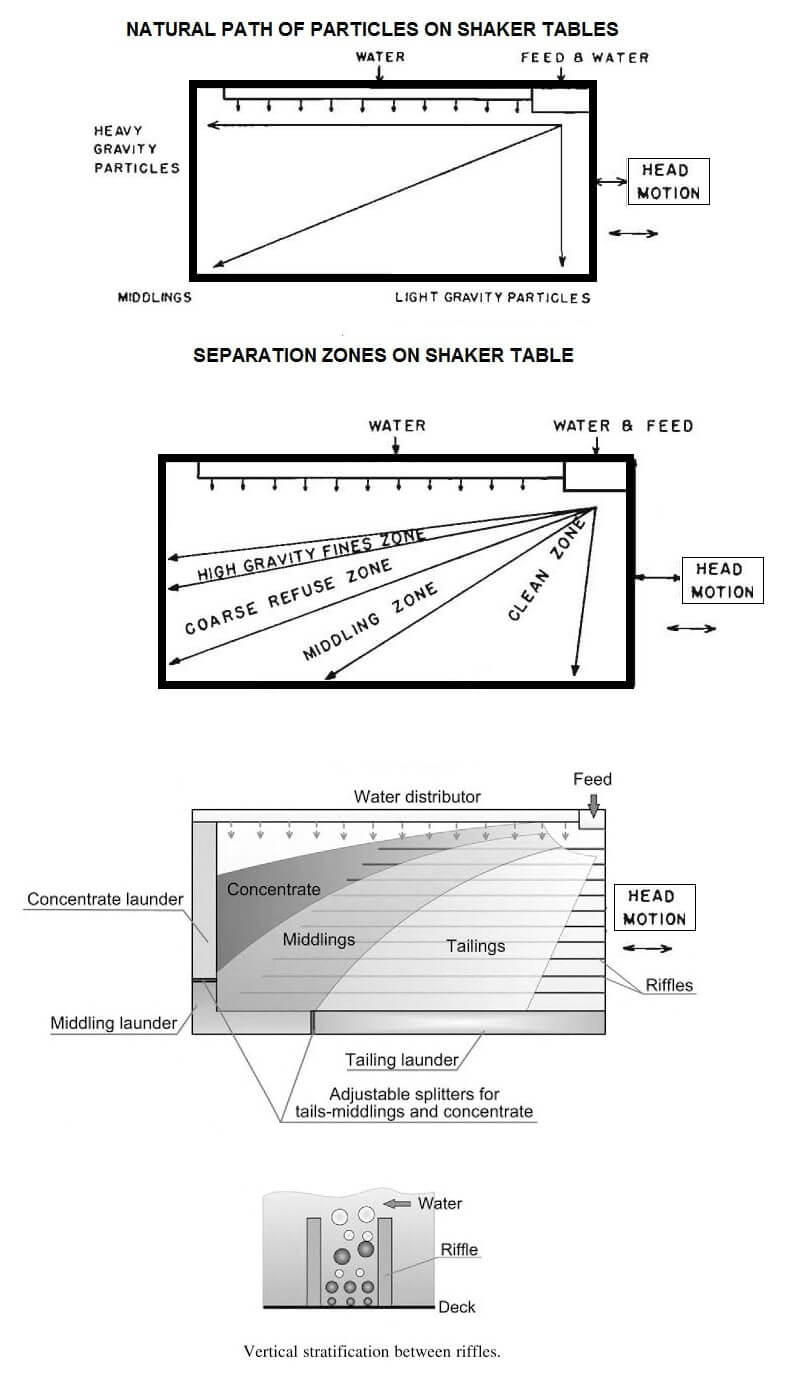

Gold Shaker Table Working Principle

Description & Technical Data

Shaking table which is also called table concentrator, it’s effective in processing precious and base metal, rare metal and non-metallic minerals, widely used in separation for Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc. The range of effective separating particle size of shaking table is 2 to 0.022 mm.

| ITEM | Unit |

Coarse ore Deck |

Fine sand Deck |

Slime Deck |

|---|---|---|---|---|

| Length | mm | 4500 | 4500 | 4500 |

| transmission end width | mm | 1830 | 1830 | 1830 |

| Concentrate end width | mm | 1530 | 1530 | 1530 |

| Maximum Feeding Size | mm | 2.0 | 0.50 | 0.15 |

| Feeding Amount | T/H | 1-2 | 0.5-1 | 0.5-0.7 |

| Feeding Density | % | 25-30 | 20-25 | 15-25 |

| Stroke | mm | 16-22 | 11-16 | 8-16 |

| Frequency | r/min | 45-48 | 18-53 | 50-57 |

| Water Amount | t/d | 80-150 | 30-60 | 10-17 |

| Transverse slope of Deck | ° | 2°30-4°30 | 1°30-3°30 | 1°-2° |

| Longitudinal slope of Deck | ° | 1.4 | 0.92 | — |

| Beneficiation Area | m2 | 7.6 | 7.6 | 7.6 |

| Cross-section Shape of Deck | rectangular | saw tooth | triangle | |

| Motor Power | KW | 1.1 | 1.1 | 1.1 |

| Transmission Mechanism | Eccentric linkage | Eccentric linkage | Eccentric linkage | |

| Weight | Ton | 1.0 | 1.0 | 1.0 |