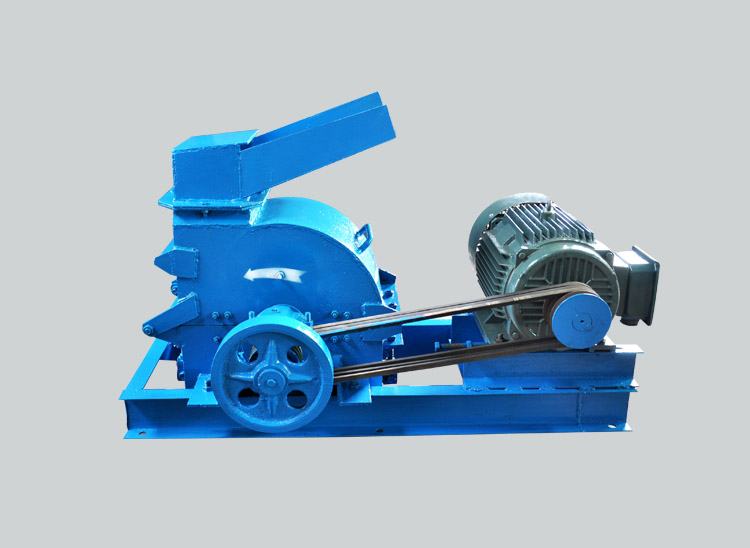

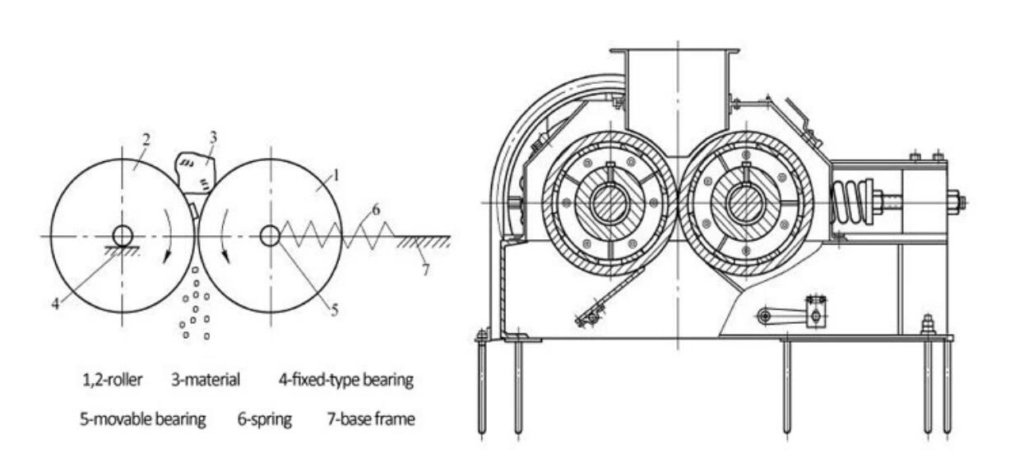

Double Roller Crusher

Double roller crusher is mainly used to crush material below the medium hardness, such as clinker mineral, coke, slag, shale, limestone and so on. It is the most suitable for small and medium non-metal mines and chemical industries to undergo secondary and fine crushing. It has the following features: simple structure, reliable performance, less flour.

Category: Crushing & Milling Equipment

Double Roller Details

Working Principle

The particles are drawn into the gap between the rollers by their rotating motion and a friction angle formed between the rollers and the particle, called the nip angle. The two rollers force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rollers.

Main Features

- The structure is simple and reasonable; the operating cost is moderate.

- High broken rate, saving energy, less wear and tear and easy maintenance.

- Have the function of fine crushing, the best choice for glass products.

- Best for crushing medium hard and especially hard materials.

- Excellent product grain size, cube shape, very few is pin sheet.

- Easy operating and maintaining.

Technical Data

| Model | Roller Diameter (mm) | Max feeding size (mm) | Discharging size (mm) | Capacity (t/h) | Power (KW) | Rotation speed (r/min) | Weight (t) |

| PGC400 | Φ400 | <25 | 2-10 | 5-10 | 11*2 | 90 | 1.1 |

| PGC600 | Φ600 | <55 | 2-10 | 15-40 | 18.5*2 | 90 | 5.2 |

| PGC800 | Φ800 | <80 | 3-10 | 18-75 | 22*2 | 82 | 7.3 |

| PGC1000 | Φ1000 | <100 | 3-10 | 32-110 | 37*2 | 76 | 11.5 |

| PGC1200 | Φ1200 | <120 | 5-10 | 48-180 | 45*2 | 60 | 17.2 |