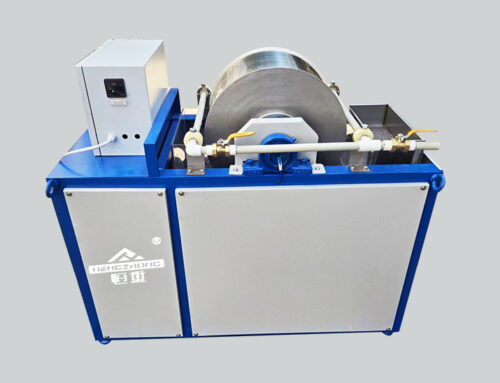

Lab Roller Crusher Description

Lab Roller Crusher roller XPS-φ250×150 crushing and screening machine is a new type of crushing equipment with a crushing belt screening function. The machine is economical to use, with uniform product particle size, good performance, and high efficiency. It is mainly used in the laboratories of geology, coal, mining, metallurgy, chemical industry, building materials, and other departments, as well as in the laboratories of colleges and research institutes, and can also be used for quality inspection and environmental protection inspection.

Lab Roller Crusher Working Principle

The lab double roller crusher uses two pieces of independently driven rollers to crush materials by squeezing, rolling, and grinding shearing forces generated by relative rotation.

When the material enters the crushing cavity of the machine, the material is affected by the tooth force of the transmission roller, forcing the material to pass between the two rollers. At the same time, it is squeezed and ground by the roller. The material begins to crush, and the crushed particles are along the tangential direction of the roller rotation, through the gap between the two rollers, it is lowered and thrown toward the machine. Large materials exceeding the gap continue to be crushed into small particles and discharged.

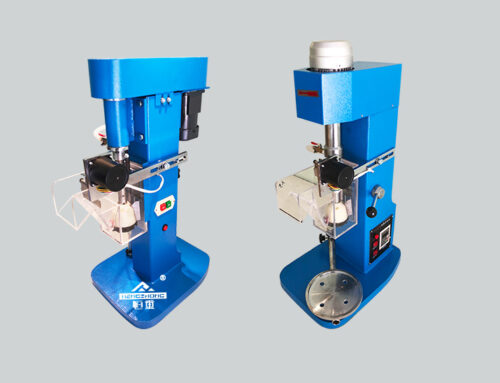

Machine Detail Pictures

Technical Parameters

| Item | Unit | XPS-φ250×150 |

| Roller size (diameter x width) | mm | φ250×150 |

| Max feeding size | mm | ≤15 |

| Discharge size | mm | 1~4 (minimum 0.4) |

| Main roller speed | r/min | 186 |

| Capacity | kg/h | 200~1200 |

| Motor | kw | 3 |

| Motor speed | r/min | 940 |

| Weight | kg | 465 |

| Dimensions (L×W×H) | mm | 1200×650×1040 |