Manganese Ore Processing Plant

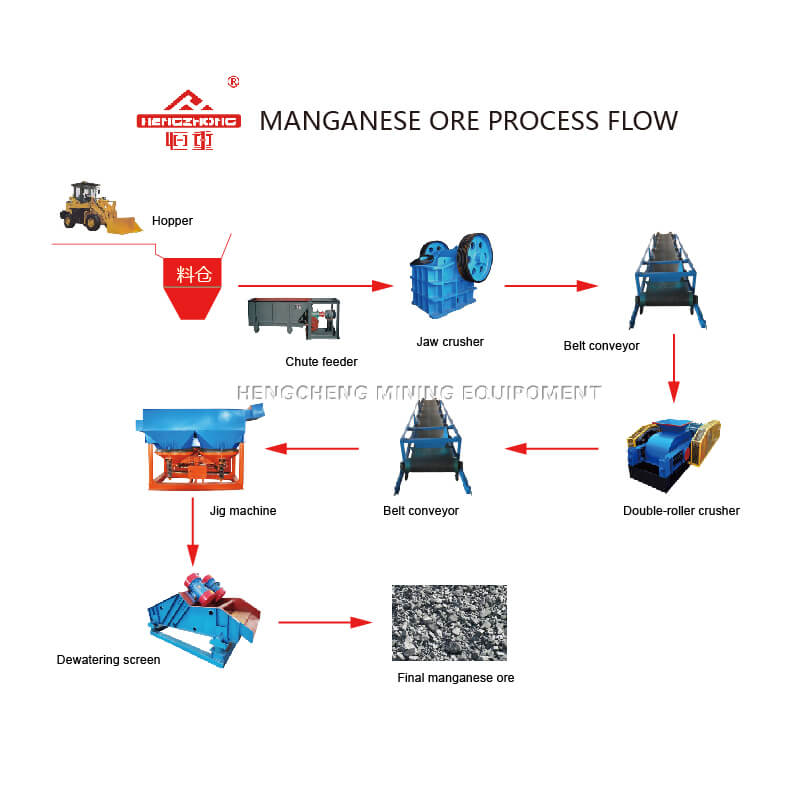

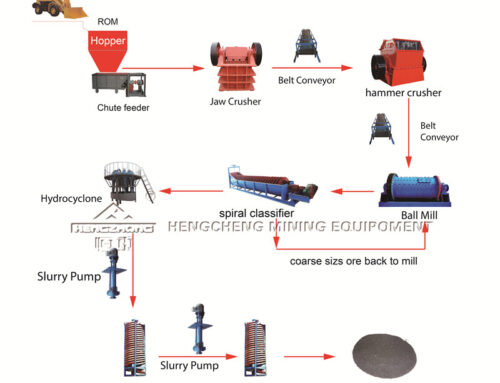

Our Company can provide the full line of manganese ore processing plants. Manganese ores are typically classified into two main types: oxide ores and carbonate ores. Oxide ores, such as pyrolusite and romanechite, are rich in manganese oxides, while carbonate ores, like rhodochrosite, contain manganese in the form of carbonates. In manganese ore beneficiation, gravity separation (re-election) is commonly used to improve ore quality. This method involves separating valuable minerals from gangue based on differences in density, using equipment like jigs, shaking tables, and spirals to concentrate manganese ores efficiently.

The most efficient and economical method for Manganese Mining is gravity separation. Manganese ore is mostly originally lumpy type from the mine area, to upgrade and remove impurity material, we need to reduce that lumpy ore into smaller sizes, and then do washing & separation, to get the final high-grade manganese ore product.

Main Machine pictures

Previous Manganese ore processing plant working video

We’re not only manganese ore processing plant supplier:

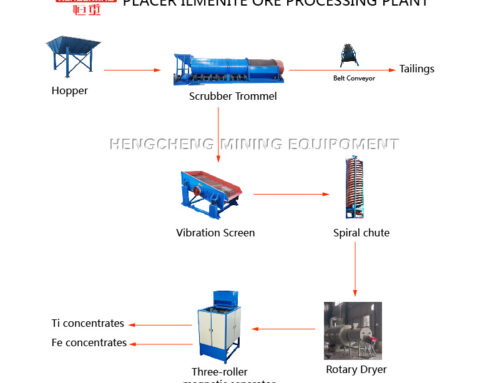

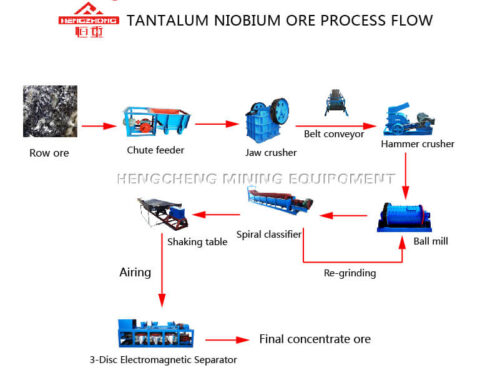

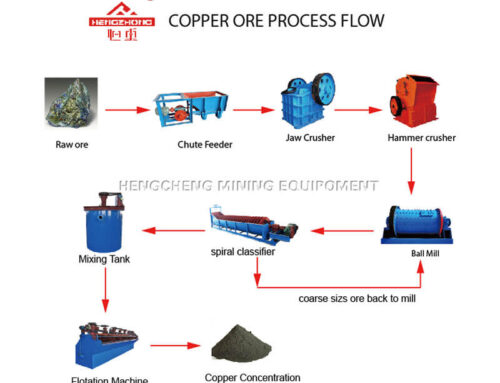

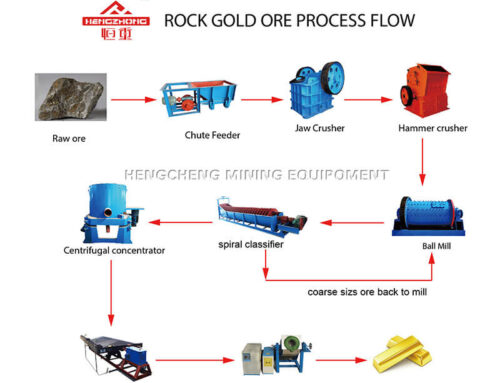

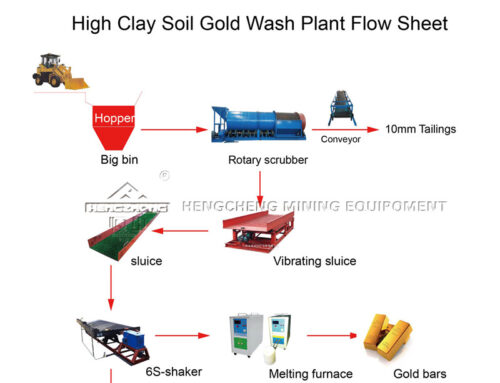

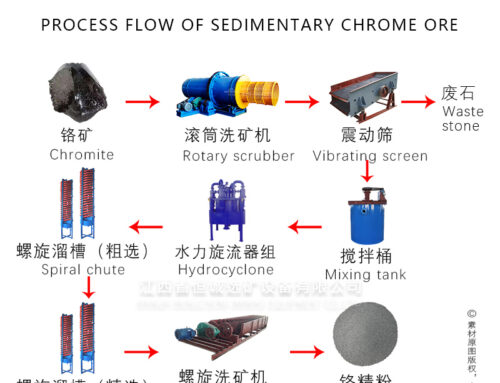

In addition to manganese mining equipment, our company also has rich experience in other mineral ore processing, such as rock gold, placer gold, rutile, ilmenite, chromite, tin, diamond, copper, iron, tungsten, Tantalum, Niobium, monazite, etc.

What we could do for every customer is one-package service:

Except for manufacturing the mining equipment, we also can provide:

- Engineering consultation,

- mineral processing experiments,

- Process Flowchart design,

- Installation and commissioning, Staff training,

All of our equipment can be customized according to your requirements.