Gravity separation is a separation method that separates minerals according to their density. When carrying out separation, in addition to various separation equipment, there must also be a medium (air, water/dense liquid or resuspension). During the separation process, the ore particles are subject to gravity (mainly centrifugal force if in the centrifugal force field), the mechanical force exerted by the equipment and the force of the medium. Motion trajectories that can eventually separate them from each other.

What is the characteristics of gravity separation?

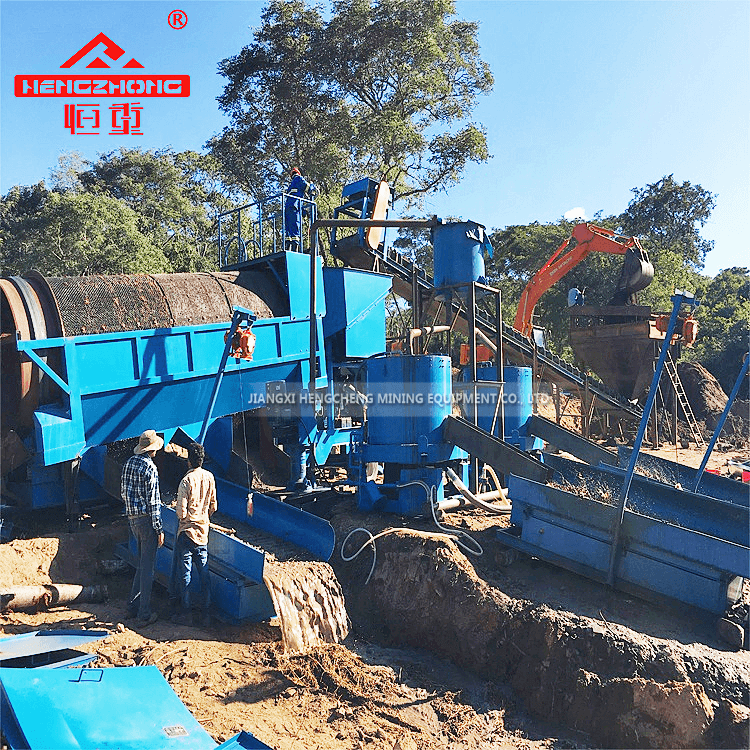

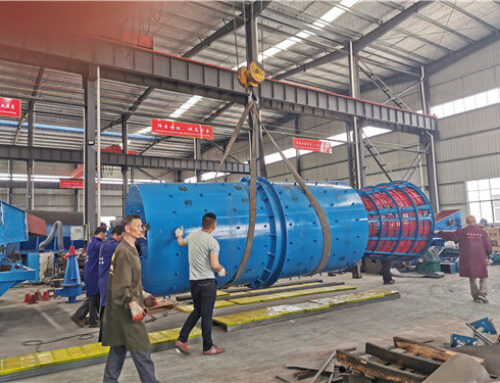

The gravity separation method has the characteristics of simple equipment structure and low operating cost, so it can be used when the conditions are suitable.

What is the applications of gravity separation?

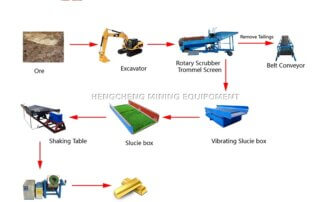

(1) Selection of precious metals such as gold and platinum;

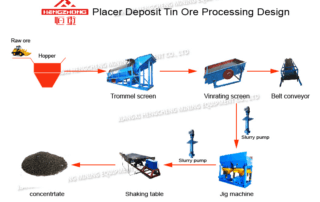

(2) Selection of tungsten and tin ores;

(3) It is widely used in the treatment of placers containing minerals containing rare metal elements, such as seashores containing zirconium and titanium minerals. Placer separation;

(4) separation of hematite and limonite;

(5) separation of manganese ore;

(6) separation of clean coal and gangue in coal preparation plants;

(7) separation of some non-metallic minerals and gangue Separation, such as the selection of asbestos, mica, kaolin, sepiolite and diamond;

(8) For non-ferrous metal ores such as copper, lead, and zinc that are mainly processed by flotation, pre-enrichment by gravity separation is also commonly used.

(9) The process of sorting according to particle size in separation, such as classification, desliming, etc., is an indispensable operation in almost all concentrators.