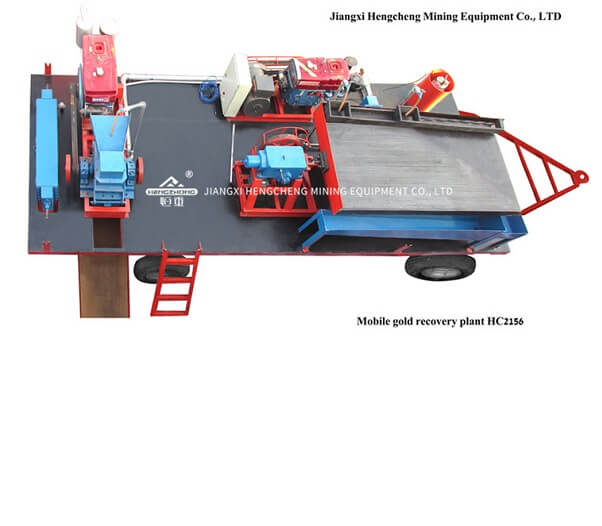

Mobile Small Scale Gold Plant

Mobile gold recovery plant is composed by hopper, rock hammer crusher, sluice box, gold separator, YC diesel generator, diesel engine, water pump and combined type frame etc, besides it equip mechanical leveling device which can support the system firmly, in order to ensure that gold particles have the optimum separation.

Machine Details Show

Description & Technical Data

Main components:

1.water pump

2. generating unit

3. electrical control cabinet

4.diesel engine

5. shaking table

6. rock hammer crusher

7.general power switch

8. Battery cell storage box

9. sluice box

10.ground wire

- crush system

the rock hammer crusher driven by 30HP diesel engine, it can break rock which is not bigger than 50mm to minus 2.8mm, in that case useful mineral can be completely liberated from the rock, then flow to gold sluice box which as rougher for separation.

- rough system

the rougher is a gold sluice box, it’s 2500mm length, 600mm width, it covered by professional gold recovery carpet.

- clean system

the concentrate get from gold sluice box still has impurities, it should have a re-separation of enrichment for the gold. Shaking table is an excellent cleaner which can separate gold perfectly with very low cost. The power is 1.1KW only.

- water system

the plant adopts an unified water supply system, it can supply 8-10 tons per hour, because of low quality of water allowed for gold separation, so the water can be recycled when it is in shortage. The power of water pump is 1.5KW only.

- gold purify device

Amalgamator/melting furnace can be added on the mobile plant according to customer’s need.

- mobile device

whole plant move by wheel, and fix on the ground by mechanical leveling supports when it working.

Technical parameter

1,Overall dimension: 5600*2100*1900mm

2,Running speed: <30km/h

3,Bearing capacity: 5t

4,Stretch distance of mechanical leveling supports: 480mm.

5,Bearing capacity of mechanical leveling supports: 64t

6,Output of generator: 8kw

7,Output of engine: 30HP

8,Output of crusher: <2.5mm(80% plus)

9,Crushing density of crusher: 30%-45%

10,Feeding density of sluice box: 18%-25%

11,Feeding density of shaking table: 20%-25%

12,Clean-up cycle of sluice box: 2h-4h

13,Capacity: 1-2t/h

14,Oil consumption: 6 L/h

Please leave your message, we will contact you asap!

Please leave your message, we will contact you asap!

Please leave your message, we will contact you asap!

Jiangxi Hengcheng Mining Equipment Co., Ltd

ADD: Guzhang Industrial Zone, Shicheng County, Ganzhou City, Jiangxi Province, China 342700

Website: www.hengchengmachinery.com

TEL & Whatsapp : +86 19970911285

Email: sales2@oremachinery.cn

Contact: Cindy Chen