Scrubber Trommel Wash Plant

Description

Rotary scrubber makes rocks and pebbles collide, rub & roll with each other in the drum. Add high-pressure water spray to decompose clay. The new type of roller washing machine has a big capability with a high degree of cleaning. It has been widely used in many sedimentary ore production lines.

Working Principle

The scrubber spins slowly, similar to a giant washing machine. It churns the fines and oversize water together, vigorously breaking up the soil matrix as well as liberating the target mineral from tough clay, mud, and rock. The disintegrated material is homogeneously slurried within the drum, whilst the autogenous load is retained within the drum by reverse flights located at the drum discharge end.

Slurry and washed oversize overflows the drum discharge throat to the concentric exit trommel. This material is then passed on to the downstream process equipment which can be in various forms such as centrifugal Concentrator, spiral chute, jig, etc.

Main Features

1. Designed to break up alluvial gravels, clays and sand.

2. High capacity and high power scrubbing.

3. The long drum of the scrubber retains material for longer, more vigorous washing for complete separation.

4. Thickening-type steel plate for the drum.

5. Heavy-duty bearing, gear and roller.

6. Wearable screen at the exit of the drum for screening.

7. One high output electrical motor driving a gear system providing efficient torque.

8. Adjustable rotary speed.

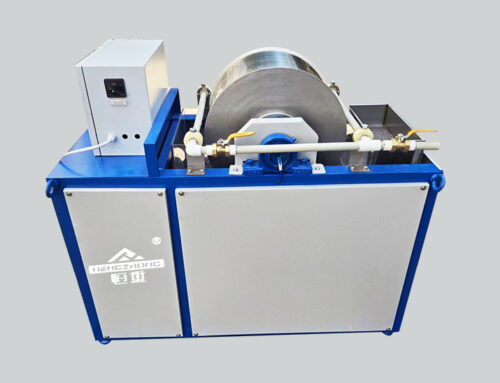

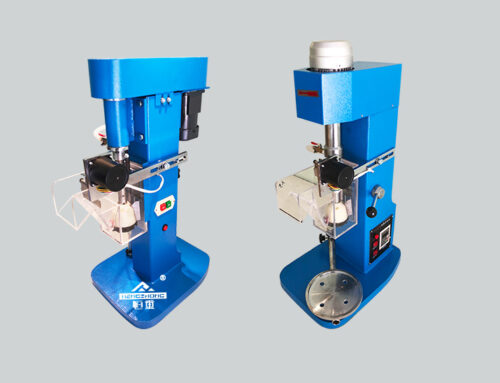

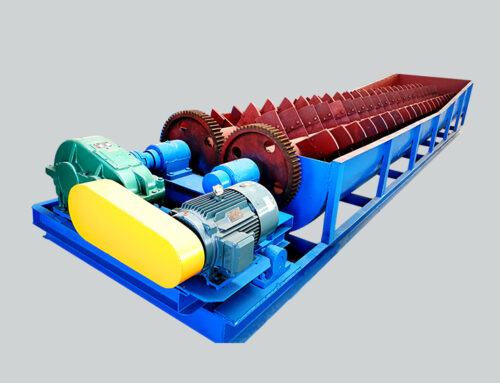

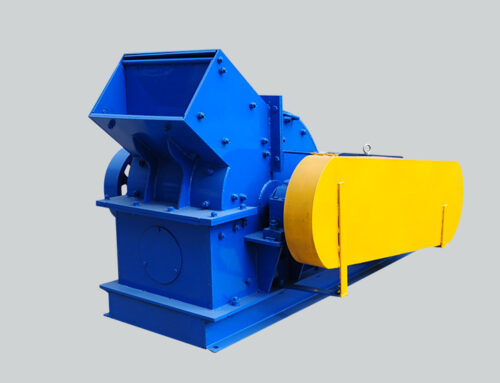

Machine Detail Pictures

Technical Parameters

| Model | Drum Size (m) | Screen mesh (mm) | Feeding size (mm) | Water pressure (Mpa) | water required (M3/t) | Capacity (T/h) | speed (r/min) | Power (Kw) | Weight (T) |

|---|---|---|---|---|---|---|---|---|---|

| RXT1030 | Φ1.0×3.0 | ≥5 | ≤100 | 0.4~0.5 | 1.5~4 | 6-10 | 25~28 | 15.0 | 4.8 |

| RXT1230 | Φ1.2×3.0 | ≥5 | ≤100 | 0.4~0.5 | 1.5~4 | 10-15 | 23~25 | 18.5 | 5.8 |

| RXT1545 | Φ1.5×4.5 | ≥5 | ≤150 | 0.4~0.5 | 1.5~4 | 15-25 | 18~22 | 30.0 | 6.9 |

| RXT1560 | Φ1.5×6.0 | ≥5 | ≤150 | 0.4~0.5 | 1.5~4 | 20-50 | 18~22 | 37.0 | 8.3 |

| RXT1845 | Φ1.8×4.5 | ≥5 | ≤170 | 0.4~0.5 | 1.5~4 | 50-80 | 20~21 | 45.0 | 11.8 |

| RXT1860 | Φ1.8×6.0 | ≥5 | ≤170 | 0.4~0.5 | 1.5~4 | 80-100 | 20~21 | 45.0 | 12.8 |

| RXT2060 | Φ2.0×6.0 | ≥5 | ≤210 | 0.4~0.5 | 1.5~4 | 100-120 | 19~20 | 55.0 | 14.8 |

| RXT2265 | Φ2.2×6.5 | ≥5 | ≤230 | 0.4~0.5 | 1.5~4 | 120-150 | 19~20 | 55.0 | 16.5 |

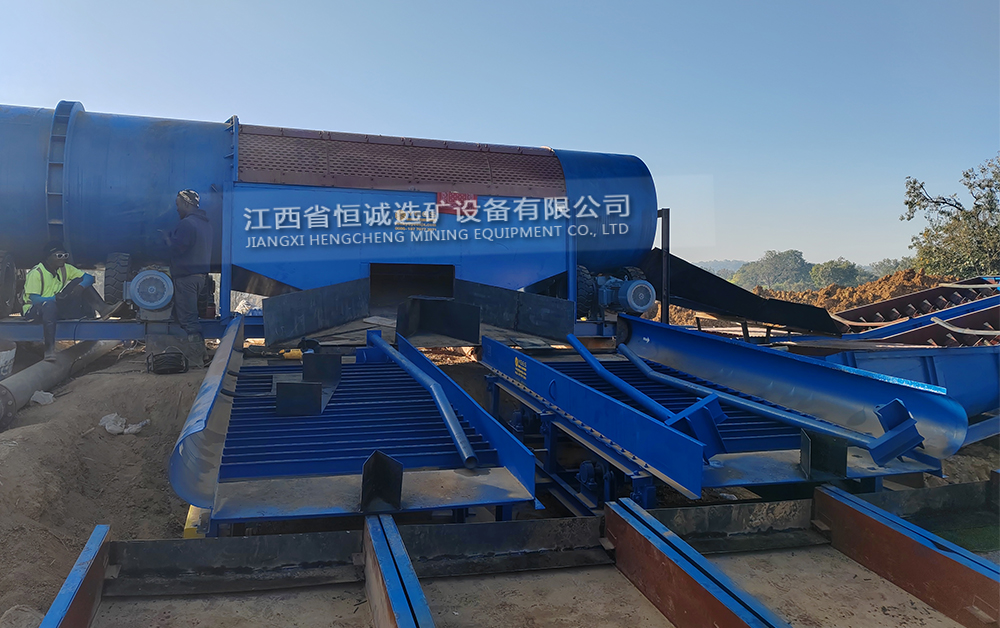

Our Machines In Clients’ Mine Site

Please leave your message, we will contact you asap!

Jiangxi Hengcheng Mining Equipment Co., Ltd

ADD: Guzhang Industrial Zone, Shicheng County, Ganzhou City, Jiangxi Province, China 342700

Website: www.hengchengmachinery.com

TEL & Whatsapp : +86 19970911285

Email: sales2@oremachinery.cn

Contact: Cindy Chen