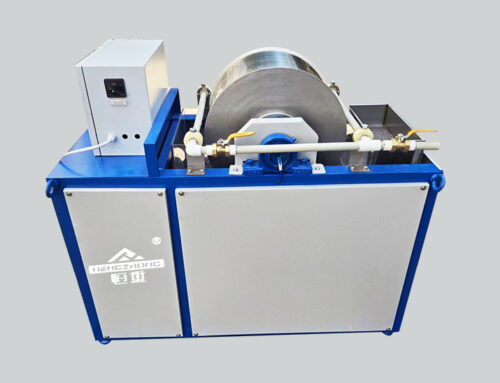

Three-Roller Magnetic Separator

The three-roller magnetic separator is a high-efficiency mineral separator designed for ore beneficiation, metal recovery, and environmental protection applications. Featuring a three-roller magnetic system with varying magnetic intensities, it ensures precise separation of magnetic and non-magnetic materials.

Category: Magnetic separation equipment

Machine Details Show

Three-roller magnetic separator application

Mineral Processing: Separation of iron ore, titanium ore, monazite, tantalum-niobium ore, and other magnetic minerals.

Waste Recycling: Recovery of metals from industrial scraps, electronic waste, and tailings.

Environmental Protection: Treatment of metal-containing wastewater/sludge for resource recycling and pollution control.

Three-roller magnetic separator working principle

Three-Stage Magnetic Separation:

First & Second Rollers (Semi-Magnetic): Equipped with 135° magnetic arc arrangement, allowing automatic discharge of minerals at a specific rotation angle for preliminary separation.

Third Roller (Full Strong Magnetism): 360° full magnetic coverage ensures strong adsorption; captured minerals are removed via a brush mechanism for complete separation.

Process: Material is evenly fed onto the rollers—magnetic particles adhere to the rotating drums, while non-magnetic materials flow away, achieving multi-stage precision sorting.

Three-roller magnetic separator parameters

| Model | Roll Dia(mm) | Roll Length(mm) | Magnetic Intensity Field(GS) | Feeding size(mm) | Capacity(t/h) | Power(kw) |

| RMS 0310 | 220/220/300 | 1000 | 2000/8000/12000 | <2 | 2-3 | 1.5*3 |

| RMS 0512 | 220/500/500 | 1200 | 1500/8000/9000 | <2 | 3-5 | 5.9 |

Remark: The diameter and length of the three rollers are customizable, while the magnetic field intensity (in Gauss) will be determined based on the specific mineral ore to be processed.

Customization & Services

Tailored Solutions: Adjustable roller count (1–3), dimensions, and magnetic intensity.

OEM Support: Design modifications for specific materials or workflows.

Technical Services: Installation guidance, maintenance training, and after-sales support.

Note: All specifications can be optimized based on customer requirements. Contact us for detailed consultations!