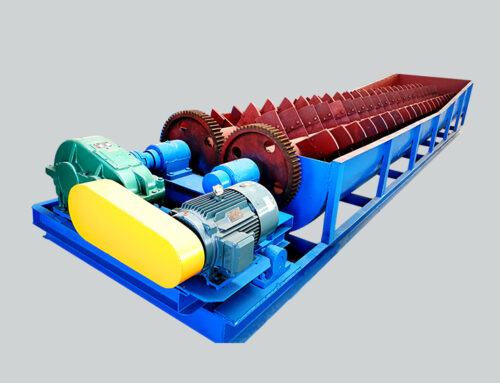

Four decks shaking table

Traditional shaker covers an area of large, relatively low processing capacity, and cost increases. However, four decks shaking table covers an area of convenience to deal with a larger capacity at lower cost;

Category: Gravity separation equipment

Description

Traditional shaker covers an area of large, relatively low processing capacity, cost increases, multi deck-shaker covers an area of inconvenience to deal with a large amount of equipment, low cost, Shaker is available in the multi-sweep the election, featuring various operations, sorting coarse sand (2-0.5 mm), fine sand (0.5-0.74), sludge (0.074) different grain level, The same bed with hyperbolic rocker mechanism, the spring box in the shaker box, the crankshaft, rod, springs, rocker and so increase the size, material unchanged. The lower bed shares a set of lower bed slope adjustment devices used in shake liner support.

Main Features

- Ingenious structure of inertial gearing, self-balanced vertical force component. No vertical jump because no vertical vibrating force. It can be installed on the building floor, or the bracket.

- Lift type, minimal consumption of friction, reduced vibration and energy-saving, non-required bulky base, quick and flexible installation.

- It adopts a fiberglass deck with a wear-resistant layer, a wear-resistant, waterproof, anti-dry, anticorrosion, non-deformed, less maintenance, and long service life.

- The deck is installed in a uniform frame Layer-by-layer, easy to install and unload, and increases processing capacity per unit area. Replace different weight blocks can change the stroke of the shaking table.

- It adopts a variable-frequency governor, easily changing the frequency of stroke to adopt different materials with different particle sizes and features.

SPECIFICATION FOR MULTI DECK SHAKING TABLE

Model | 3LYG | 4LYG | |||||||

| Deck type | Coarse ore Deck | Fine sand Deck | Slime Deck | Coarse ore Deck | Fine sand Deck | Slime Deck | |||

| Beneficiation area (m2) | 7.6 X 3 | 7.6 X 3 | 7.6 X 3 | 7.6 X 4 | 7.6 X 4 | 7.6 X 4 | |||

| Deck Size | Length (mm) | 4500 | 4500 | 4500 | 4500 | 4500 | 4500 | ||

| Transmission end width (mm) | 1850 | 1850 | 1850 | 1850 | 1850 | 1850 | |||

| Concentrate end width (mm) | 1550 | 1550 | 1550 | 1550 | 1550 | 1550 | |||

| Maximum feeding size (mm) | 2 | 0.5 | 0.074 | 2 | 0.5 | 0.074 | |||

| Capacity (t/h) | 4-5 | 2-3 | 1.5-2.5 | 5-6.5 | 3-5 | 2-3.5 | |||

| Feeding density (%) | 20-30 | 18-25 | 15-20 | 20-30 | 18-25 | 15-20 | |||

| Stroke (mm) | 8,10,12,15,18,20,22 | ||||||||

| Frequency of stroke (r/min) | 270—360 (variable-frequence) | ||||||||

| Water consumption (t/h) | 0.7-1 | 0.4-0.7 | 0.4-0.7 | 0.7-1 | 0.4-0.7 | 0.4-0.7 | |||

| Groove shape of deck | Available Rectangular, Saw-tooth, Triangle | ||||||||

| Power (Kw) | 1.5Kw | Dimensions (mm) | 6330×2450×2660 | ||||||