Machine Details Show

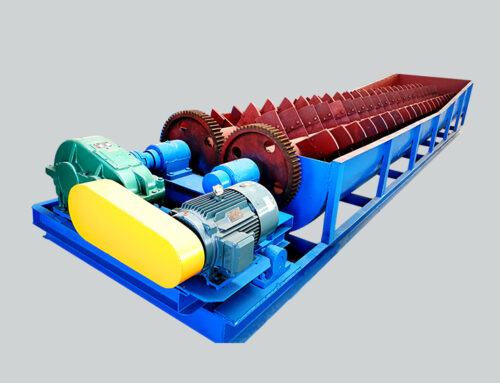

Spiral Separator Working Prinicple

A spiral chute works under the force of water flow, gravity, inertial centrifuge, and friction. The slurry is pumped to the top of the spiral, and it enters a feed distributor that evenly distributes the feed to each spiral concentrator. The design and shape of the spiral make it work when combined with gravitational acceleration. As the slurry travels the spiraling path down the spiral, mineral grains settle and start sorting according to size, density, and to a lesser extent shape. Low-density particles are carried with the bulk of the water toward the outside of the spiral, while particles with the greatest density migrate toward the inside of the spiral.

Main Features

- Reasonable structure and small occupation area;

2. High recovery, high efficiency, and precise separation;

3. Light in weight, rust and corrosion-resistant;

4. Simple installation and Minimal maintenance requirements;

5. Low operating cost and long operating life;

6. Reliable running with minimal operator attention;

7. Strong adaptability to fluctuation of feeding amount, density, size, and grade.

Spiral Chute Technical Data

| Model | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 |

|---|---|---|---|---|---|

| Outside dia(mm) | 1500 | 1200 | 900 | 600 | 400 |

| pitch(mm) | 540,720 | 900,720,540 | 675,540,405 | 450,360,270 | 240,180 |

| Pitch Dia Ratio | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.75,0.6,0.45 | 0.6,0.45 |

| Lateral slope | 9° | 9° | 9° | 9° | 9° |

Maximum starts per column | 4-2 | 4-2 | 4-2 | 3 | 2 |

| Feeding Size(mm) | 0.3-0.03 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 |

| Feeding Density(%) | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 |

| Capacity(T/H) | 8-6 | 4-6 | 2-3 | 0.8-1.2 | 0.15-0.2 |

| Dimension (mm) | 1560*1560*5230 | 1360*1360*5230 | 1060*1060*4000 | 700*700*2600 | 460*460*1500 |

| Weight (Kg) | 800 | 600 | 400 | 150 | 50 |

Our Machines In Clients’ Mine Site

Please leave your message, we will contact you asap!

Please leave your message, we will contact you asap!

Please leave your message, we will contact you asap!

Jiangxi Hengcheng Mining Equipment Co., Ltd

ADD: Guzhang Industrial Zone, Shicheng County, Ganzhou City, Jiangxi Province, China 342700

Website: www.hengchengmachinery.com

TEL & Whatsapp : +86 19970911285

Email: sales2@oremachinery.cn

Contact: Cindy Chen