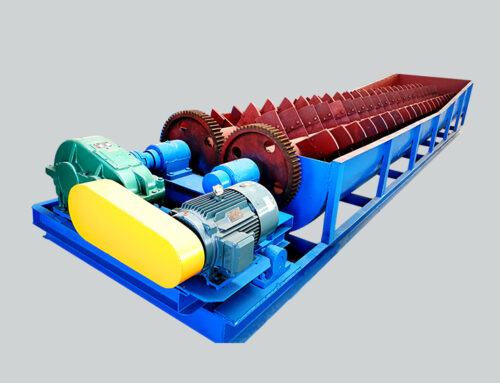

Spiral Classifier

Spiral classifier is widely used to control material size from the ball mill in the beneficiation process, separate mineral sand and fine mud in the gravity concentration, and clean mud and water in the washing mineral process.

Category: Washing & Screening equipment

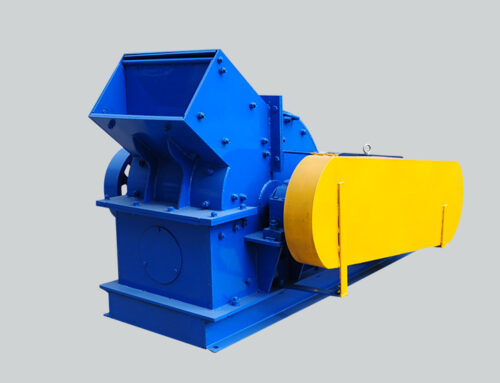

Spiral Classifier Machine Show

Spiral Classifier Application

Spiral classifier has the characteristics of simple structure, reliable work, and convenient operation.

- Working with a ball mill in mineral concentrating that forms a closed circuit operation to distribute ore sand;

- Classification of ore sand and fine mud in separation plant;

- Granularity classification of slurry and desliming and dehydration in the process of metal dressing;

- Operation of desliming, dewatering, and other operations in ore washing operations.

Working Principle

Working Principle

The ground pulp is fed into the tank from the inlet in the middle of the settlement region, and the

slurry classification sedimentation area is under the inclined tank. The spiral with low-speed rotation stirs the slurry, so that the fine particles rise, and the coarse particles sink to the bottom of the tank. The overflow weir is above the bearing center which is under the screw shaft, and is underneath the overflow end.

| Model | Spiral Diameter (mm) | Length of pool (mm) | Rotation Speed (r/min) | Drive motor | Lift motor | Dimensions (mm) | Weight(t) |

|---|---|---|---|---|---|---|---|

| FG-3 | 300 | 3000 | 12-30 | 1.1 | – | 3850*490*1140 | 0.7 |

| FG-5 | 500 | 4500 | 8-12.5 | 1.1 | – | 5430*680*1480 | 1.6 |

| FG-7 | 700 | 5500 | 6-10 | 3.0 | – | 6270*980*1820 | 2.7 |

| FG-10 | 1000 | 6500 | 5-8 | 5.5 | – | 7590*1240*2380 | 4.0 |

| FC-10 | 1000 | 8400 | 5-8 | 7.5 | – | 9600*1240*2680 | 6.0 |

| FG-12 | 1200 | 6500 | 4-6 | 7.5 | 2.2 | 8180*1570*3110 | 8.5 |

| FC-12 | 1200 | 8400 | 4-6 | 7.5 | 2.2 | 10370*1540*3920 | 11.0 |

| 2FG-12 | 1200 | 6500 | 4-6 | 15 | 4.4 | 8230*2790*3110 | 15.8 |

| 2FC-12 | 1200 | 8400 | 4-6 | 15 | 4.4 | 10370*2790*3920 | 17.6 |

| FG-15 | 1500 | 8300 | 4-6 | 7.5 | 2.2 | 10410*1880*4080 | 12.5 |

| FC-15 | 1500 | 10500 | 4-6 | 7.5 | 2.2 | 12670*1820*4980 | 16.8 |

| 2FG-15 | 1500 | 8300 | 4-6 | 15 | 4.4 | 10410*3390*4080 | 22.1 |

| 2FC-15 | 1500 | 10500 | 4-6 | 15 | 4.4 | 12670*3370*4890 | 30.7 |

| FG-20 | 2000 | 8400 | 3.6-5.5 | 11-15 | 3.0 | 10790*2530*4490 | 20.5 |

| FC-20 | 2000 | 12900 | 3.6-5.5 | 11-15 | 3.0 | 15610*2530*5340 | 28.5 |

| 2FG-20 | 2000 | 8400 | 3.6-5.5 | 22-30 | 6.0 | 11000*4600*4490 | 35.5 |

| 2FC-20 | 2000 | 12900 | 3.6-5.5 | 22-30 | 6.0 | 15760*4600*5640 | 48.7 |

| FG-24 | 2400 | 9130 | 3.67 | 15 | 3.0 | 11650*2910*4970 | 25.7 |

| FC-24 | 2400 | 14130 | 3.67 | 18.5 | 4.0 | 16580*2930*7190 | 41 |

| 2FG-24 | 2400 | 9130 | 3.67 | 30 | 6.0 | 12710*5430*5690 | 45.8 |

| 2FC-24 | 2400 | 14130 | 3.67 | 37 | 8.0 | 17710*5430*8000 | 67.9 |

| 2FG-30 | 3000 | 12500 | 3.2 | 40 | 8.0 | 16020*6640*6350 | 73 |

| 2FC-30 | 3000 | 14300 | 3.2 | 40 | 8.0 | 17091*6640*8680 | 84.8 |